Regular maintenance

Lynx 2000G

Perfect Combination of Precision and Stability

These machine are suitable for machining medium and small-sized shaft and disc parts, capable of turning threads, arcs, cones, and curved surfaces. It is widely used in industries such as plumbing, valves, electrical appliances, instruments, automobiles, motorcycles, and bearings.

TCK25Y/TCK50Y Series

Spare parts supply

On-site installation service

Customized design

Highlights

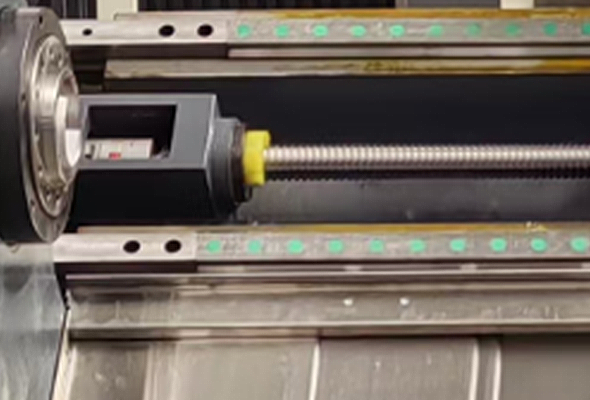

Advantages of High-Precision Ball Screws

- ● Prevent deformation

- ● High precision and durability

Advantages of Spindle Seat Casting

- ● One-piece formation with high rigidity

- ● Vibration suppression and improved accuracy

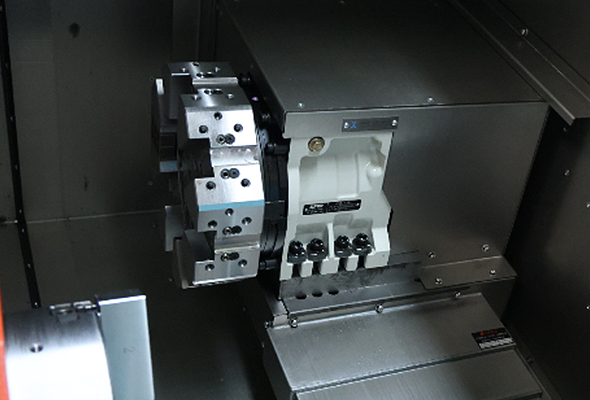

Efficient Tool Change System

- ● High-load servo motor

- ● Non-retractable tool changer technology

- ● Fast tool change, time-saving

High-Rigidity Tailstock Rail Design

- ● Ensures rigidity and accuracy

- ● Improves wear resistance and extends lifespan

Product Specifications

| Specifications | unit | TCK50Y | TCK25Y |

|---|---|---|---|

| Max.swingdia.overbed | mm | 640 | 510 |

| Max.swingdia.overside | mm | 380 | 150 |

| Max.work piece length | mm | 400/700/1500 | 235 |

| Max.bar capacity | mm | 55/75 | 44 |

| Max.processng diameter(plate) | mm | 300/450/450 | 250 |

| Spindle nose | GB59001 | A2-6/8 | A2-5 |

| spindle bore | φ/mm | 66/86/86 | 56 |

| Spindle speed | r/min | 50-3000 | 50-4500 |

| Spindleshift mode | / | stepless speed control | stepless speed control |

| Spindle motor power | KW | 11/15/15 | 7.5/5.5 |

| Chucktype | / | Hydraulic chucks | Hydraulic chucks |

| Chucksize | lnch | 10 | 6 |

| Power turet model no | / | TCSDY80H-12T-330 | BW70-Y-35-BMT40-12T-4L |

| X-axis rapid traverse | m/min | 18 | 24 |

| Z-axis rapid traverse | m/min | 18 | 24 |

| X-axis servo motor torque | N.m | 15 | 10 |

| Z-axis servo motortorque | N.m | 15 | 10 |

| X-axis travel | mm | 240/260/260 | 135 |

| Y-axis travel | mm | ±45 | ±30 |

| Z-axis travel | mm | 500/800/1500 | 370 |

| Guide waytype | / | rails | rails |

| live tool holder | / | BMT45 | BMT40 |

| Tool shank size | mm | 25X25/032 | 20X20/025 |

| Tailstock type | / | Hydraulically | Hydraulically |

| Tailstock qulldia | φ/mm | 70/90 | 70/90 |

| Tailstock qulltravel | mm | 80 | 80 |

| Totalrated power | KW | 24 | 18 |

| Net weight | kg | 3400/4100/5100 | 2500 |

| Machine dimension(LxW×H) | (mm) | 2600/3370/4100×2000×2100 | 1810×1480×1940 |

Catalog

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

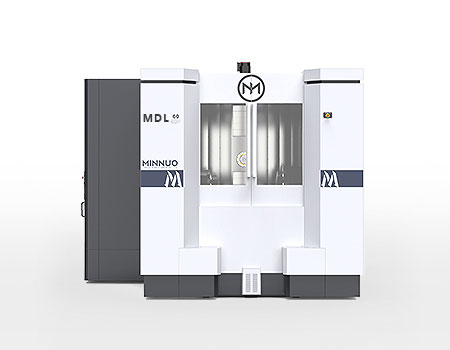

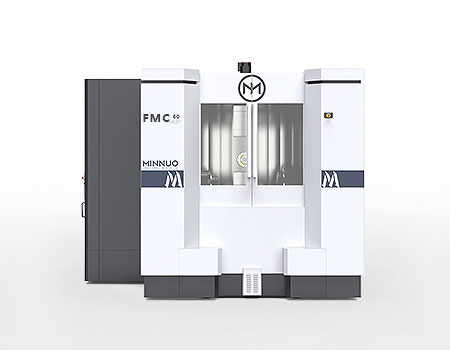

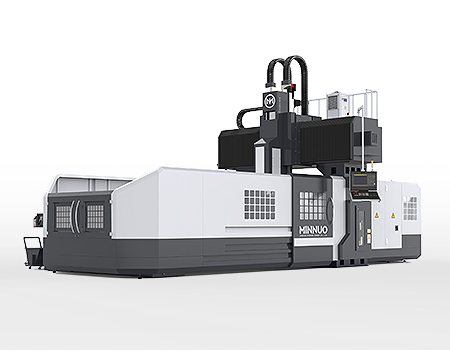

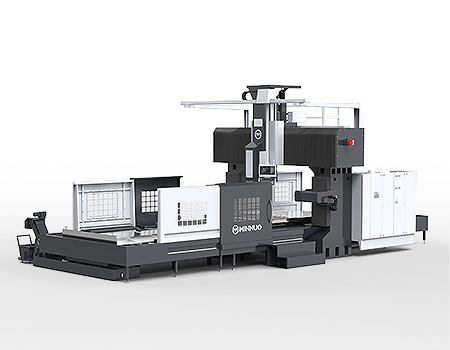

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

WhatsApp(Tel):

Email:

×