Regular maintenance

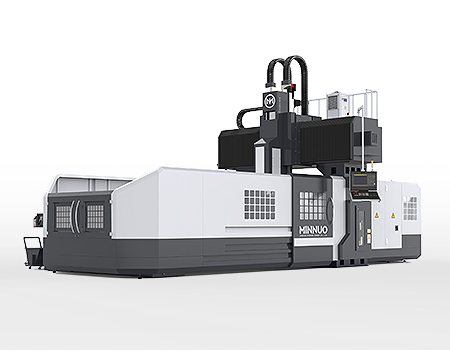

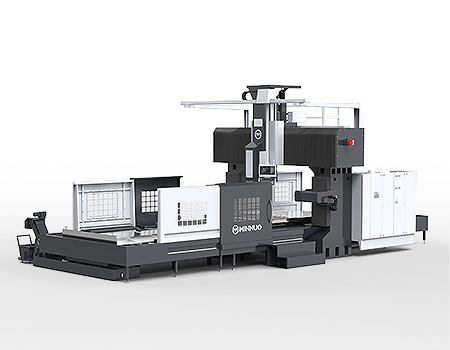

Lynx 2000G

Precision Control and Efficient Machining

This CNC gantry machining center integrates advanced gearbox and rotary table technology, enhancing precision and efficiency.

XH2014/XH3019 Series

Spare parts supply

On-site installation service

Customized design

Highlights

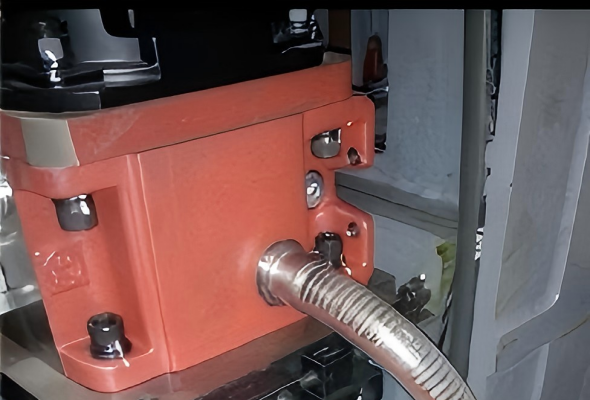

Imported Variable Speed Gearbox

- ● Smooth high-speed performance, adaptable to various machining needs

- ● Automatic gear shifting, enhancing cutting efficiency

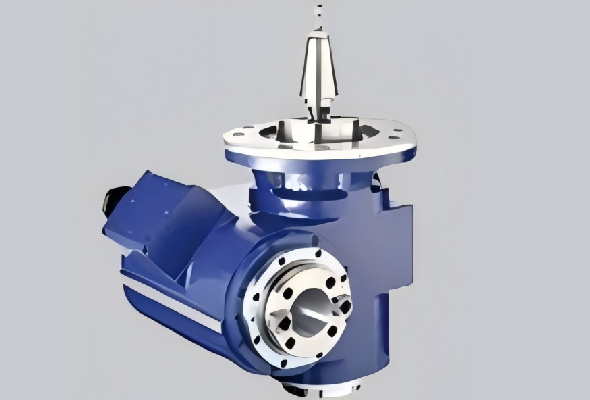

Vertical-Horizontal Dual Output Milling Head

- ● Flexible vertical-horizontal switching, suitable for multi-station machining

- ● High rigidity, supports heavy-duty cutting

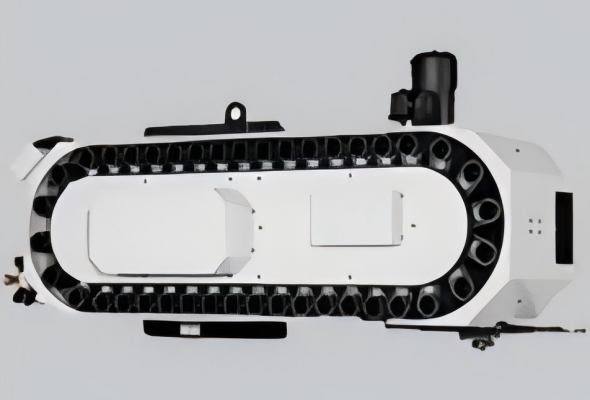

Chain Tool Magazine

- ● Large capacity, supports various tool configurations

- ● Fast tool changing, stable operation

Product Specifications

| Model | unit | XH2014 | XH2514 | XH2519 | XH3019 | |

|---|---|---|---|---|---|---|

| Workbench | Workbench Width | mm | 1200 | 1500 | ||

| Workbench Length | mm | 2000 | 2500 | 2500 | 3000 | |

| Workbench Load | kg | 5000 | 6000 | 7000 | 8000 | |

| T-slot width/spacing/quantity | 22×140×7 | 22×160×9 | ||||

| Machining range X-axis travel | X-axis travel | mm | 2100 | 2600 | 2600 | 3100 |

| Y-axis travel | mm | 1400 | 1900 | |||

| Z-axis travel | mm | 800 | 900 | |||

| Distance from spindle face to table | mm | 150-950 | 150-1050 | |||

| Distance between gantry columns | mm | 1400 | 1900 | |||

| Spindle | Spindle specification | BT50-190 | BT50-190 | |||

| Spindle motor power | kw | 15/18.5 | 15/18.5 | |||

| Spindle speed | rpm | 6000 | 6000 | |||

| Number of tools | T | 24 | 24 | |||

| XYZ axis feed speed | mm/min | 1-8000 | 1-8000 | |||

| XYZ axis rapid traverse speed | m/min | 12/12/10 | 12/12/10 | |||

| Positioning accuracy (semi-closed loop) | X-axis positioning accuracy | mm | 0.016 | 0.018 | 0.018 | 0.020 |

| Y-axis positioning accuracy | mm | 0.015 | 0.015 | 0.015 | 0.015 | |

| Z-axis positioning accuracy | mm | 0.015 | 0.015 | 0.015 | 0.015 | |

| Repeat Positioning Accuracy (Semi-closed loop) | X-axis positioning accuracy | mm | 0.012 | 0.012 | 0.012 | 0.012 |

| Y-axis positioning repeatability | mm | 0.010 | 0.010 | 0.010 | 0.010 | |

| Z-axis positioning repeatability | mm | 0.010 | 0.010 | 0.010 | 0.010 | |

| Overall dimensions | mm | 6300×3800×4700 | 7300×3800×4700 | 7300×4300×4900 | 8300×4300×4900 | |

| Overall machine weight | T | 15 | 17.5 | 20 | 23 | |

Catalog

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

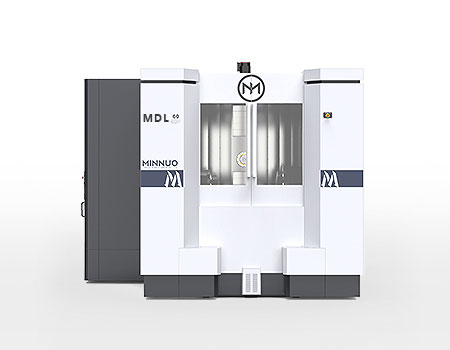

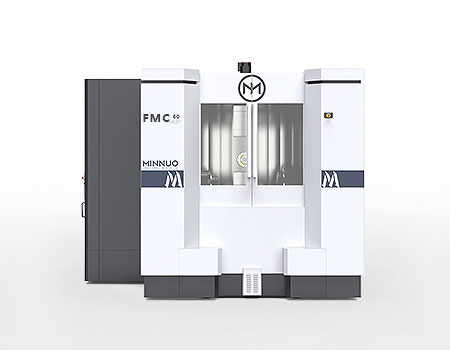

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

WhatsApp(Tel):

Email:

×